I had an extremely exciting experience to work for Molex, a highly specialized and massive multinational tech manufacturer, distributor, and supply chain comprised of numerous distributors worldwide. For Molex, I ghost wrote B2B blogs for experts in the fields of electricity and tech distribution. I also wrote training material for new products.

Blog Posts

I worked as a ghost writer for highly specific blog posts for Molex. This required me researching the content, interviewing the experts, and writing blogs in the Molex’s knowledgeable yet laid-back tone.

DISTRIBUTOR OF THE YEAR BLOG POST

For this first blog post I interviewed and wrote for Molex’s Vice President of Global Distribution. It congratulates the winners for Molex’s auspicious “Distributor of the Year” awards, which include global, European, American, and Asian Pacific South winners. I skip the long list of victors in the version of the blog below, but you can read the full blog on Molex’s Experience page.

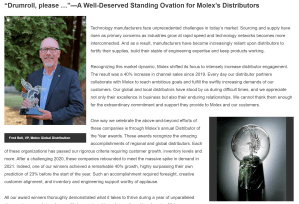

“Drumroll, please …”—A Well-Deserved Standing Ovation for Molex’s Distributors

Technology manufacturers face unprecedented challenges in today’s market. Sourcing and supply have risen as primary concerns as industries grow at rapid speed and technology networks becomes more interconnected. And as a result, manufacturers have become increasingly reliant upon distributors as a way to fortify their supplies, build their stable of engineering expertise and keep products working.

Recognizing this market dynamic, Molex shifted its focus to intensely increase distributor engagement. The result was a 40% increase in channel sales since 2019. Every day our distributor partners collaborate with Molex to reach ambitious goals and fulfill the swiftly increasing demands of our customers. Our global and local distributors have stood by us during difficult times, and we appreciate not only their excellence in business but also their enduring relationships. We cannot thank them enough for the extraordinary commitment and support they provide to Molex and our customers.

One way we celebrate the above-and-beyond efforts of these companies is through Molex’s annual Distributor of the Year awards. These awards recognize the amazing accomplishments of regional and global distributors. Each of these organizations has passed our rigorous criteria requiring customer growth, inventory levels and more. After a challenging 2020, these companies rebounded to meet the massive spike in demand in 2021. Indeed, one of our winners achieved a remarkable 40% growth, highly surpassing their own prediction of 23% before the start of the year. Such an accomplishment required foresight, creative customer alignment and inventory and engineering support worthy of applause.

All our award winners thoroughly demonstrated what it takes to thrive during a year of unparalleled changes in our market and exemplify true partnership and commitment to advancing Molex as a premier supplier in our industry. We are privileged to celebrate the winners of our 2021 Distributor of the Year awards…

We expect 2022 to be another fantastic year of enormous growth for Molex and our partners as we encourage everyone to aspire to exceed expectations in support of our joint customers. Together we can collaborate, set goals and strategize to achieve our vision of customer-first growth.

Creating Connections for Life extends beyond networks in technology. More importantly, Molex connections also reflect the powerful relationships Molex has built with its distributors around the world. These partnerships ignite significant advantages for our joint customers each and every day. Congratulations to all!!

GROUND-FAULT-CIRCUIT-GENERATOR BLOG POST

For this next blog post, I interviewed Molex’s Global Product Marketing Manager in order to write a blog explaining OSHA’s new regulations on Ground-Fault-Circuit-Interrupters (GFCIs) and promote Molex’s newest, advanced GFCI to date.

The Shocking Benefits of GFCIs

Pursuing safety in electrical and industrial work and fulfilling all Occupational Safety and Health Administration (OSHA) code require allocation of time and resources. Because of this, it is imperative that manufacturers, distributors and plant managers in these industries ensure that all their equipment is up to date in accordance with OSHA. Ground-fault circuit interrupters (GFCIs) play a necessary role in OSHA code. The benefits, though, of GFCIs extend way beyond simply complying with the law.

GFCIs and Safety

Safety in the industrial work setting has been a key concern for Woodhead for over a century. One way Woodhead promotes a safer work environment is through leading safety seminars across the country. During these seminars, people often confuse GFCI protection with that of circuit breakers. What is important to remember is that in the electrical industry, there are specific modes of providing very different protection. Circuit breakers protect the facility by preventing the overdraw of current, which creates a heat source that can cause a fire. GFCIs provide personal protection by interrupting a ground-fault break, as could happen when an employee stands in a puddle while using a power tool. If the power tool is plugged into a power source without a GFCI, the circuit may continue into the puddle through the user, causing serious injury or death. A circuit would not protect the person in this scenario because it only supplies facility—not individual—safety.

In industrial environments, employees often utilize GFCIs in a temporary capacity through portable GFCIs. Portable GFCIs are attached to the power cords of power tools and other technology and protect any electrical current flowing from downstream the GFCI. Unlike in home and offices, power circuits are not safely tucked away behind walls. In fact, it’s not uncommon for a power network to lie on the ground where workers can step on it or drive carts and forklifts over it. When a person walks or drives over an open circuit, the current may break and jolt through the worker. Portable GFCIs help ensure that no employee is electrocuted by this open power network.

Whether a work area is slightly wet because of puddles, humidity or dew, or drenched from high-pressure washing as in a meat processing plant, GFCIs play an indispensable role in guarding individuals from electrocution. These cases require a watertight GFCI rather than a standard heavy-duty connection GFCI in order to keep the plug-connector arrangement dry. Manufacturers offer a variety of waterproof GFCIs. For example, at Molex-Woodhead we have four levels of enclosure ratings:

- Raintight

- High-pressure washdown

- Submersible

- IP69K (launching Q4 of 2022)

The IP69K-rated GFCI, which is unique to Woodhead, withstands water pressure at a level recognized within the industry as the ultimate goal for GFCIs. Based upon the user’s application, the employee or employer may need to incorporate a more watertight GFCI to ensure greater individual safety.

GFCIs and Efficiency

Not only do the right GFCIs provide safety in the work environment, but they also promote higher levels of productivity. One of the biggest reasons people stop using their GFCIs is nuisance tripping. Nuisance tripping occurs when the GFCI keeps tripping unnecessarily and halting work. Oftentimes, workers or a company will remove the GFCI from a power circuit in response to nuisance tripping and continue the project unprotected. Instead of making this extremely dangerous decision, it would be more efficient and safer for the users to select a higher-grade GFCI.

OSHA-compliant, watertight GFCIs, like those offered by Woodhead, would not only have better protected the workers on a rainy day, but would also have saved the workers time and energy spent going up and down the ladders searching for what caused the nuisance tripping.

Besides waterproof solutions, automatic- and manual-reset GFCIs affect the productivity of a warehouse or plant. Automatic-reset GFCIs turn on immediately when power is restored to a system and are best applied to permanent fixtures such as lighting and HVAC. For manual-reset GFCIs, on the other hand, in order to restore power to the circuit, you are forced to hit the reset button whenever the electricity goes off and then back on. Manual-reset GFCIs function best in temporary settings with power tools.

Another factor in limiting nuisance tripping is cord size. A good rule of thumb is that when the load is closer to the GFCI, it is more protected and there is less chance of nuisance tripping. If your portable GFCI has an 18- or 12-inch lead, then it remains comfortably close to the load. But if the GFCI is placed in the main circuit panel, it includes the lead of the electrical wire from the load center to the receptacle, plus whatever is plugged into the receptacle. That additional amount of wire builds potential for more nuisance tripping and less workplace efficiency.

OSHA’s EOL Code

GFCI technology is constantly evolving to defend users against dangers in the workplace. Recent OSHA GFCI safety standards reflect this. Updated OSHA code requires all GFCIs manufactured after May 5, 2021, to have an automated EOL feature, which either sets off an alarm or shuts off the GFCI and the circuit completely if the GFCI fails. This new enforcement stems from extremely rare events of GFCIs dying without their users knowing. In these cases, a worker plugged in the GFCI, believing it would provide protection from electrical injury, but the failed GFCI allowed dangerous levels of current to flow to the worker. Although these scenarios were quite rare, EOL advancement in GFCI technology better ensures employees’ safety, preventing a dead GFCI from being used by accident.

You may be worried that the code enforces a complete replacement of GFCIs that don’t have EOL indicators. This—hopefully to your relief—is not the case. According to the new code, the GFCI must comply with the criteria that were in place as of the date of manufacture regarding appropriateness for personal protection. The code still permits sales channels, like manufacturers and distributors, to sell GFCIs without EOL indicators past May 5, 2021, as long as the older GFCIs have a date of manufacturer prior to May 5, 2021. To be clear, GFCIs without EOL indicators still provide ample security, but there is the slight chance they may fail without users knowing.

Woodhead’s New IP69K

One way to certainly abide by OSHA’s new GFCI safety regulations is to go with Woodhead’s Underwriters Lab 943 certified GFCIs. As mentioned before, our newest IP69K-rated model provides an unprecedented level of water protection, distinct to Woodhead, and we are excited for its launch in Q4 of 2022. Besides IP69K, Woodhead supplies ample GFCIs for industrial environments. We will work with you to ensure you are fitted with the GFCIs that best protect your employees, comply with OSHA code and fulfill your business’s particular needs.

Training Material

Unfortunately, I am unable to share any training material, or, “Learning Locker Scripts,” as they are called at Molex, because they contain confidential information. The purpose of these scripts was to prepare trainers to present new products to sales teams and tests sales teams’ mastery of the new products. I took information from a new-product deck and broke it down into rational sections which describe the features of the new product and the solution it provides. Then, I prepared a short questionnaire to help the trainer test the sales teams’ understanding.